SUSTAINABILITY: WE DON'T JUST TALK ABOUT IT. WE BUILD IT IN.

We’re serious about the future of this planet—which means rethinking how products are made from the ground up. Our approach reduces waste and emissions, using smart design and smarter production. No fluff, just action

Zero waste? It’s not a stretch—it’s science.

We use Selective Laser Sintering (SLS), a precision 3D printing process that fuses polyamide powder into solid frames, one ultra-thin layer at a time. This means no molds, no offcuts, and almost no waste. And what little is left? It gets recycled right back into production

Made to order. No stockpiles. No waste. No MOQs.

We only produce what’s needed—nothing more. That means no warehouses full of unsold frames and no giving in to outdated industry standards like excessive Minimum Order Quantities (MOQs). By manufacturing on demand, we stay lean, avoid overproduction, and drastically cut waste before it even begins. Smart for the planet, smart for production

Tree planting? Still relevant. Still necessary.

We contribute to Lifegate’s Zero Impact Project, helping offset the emissions we do generate by planting trees. It’s not a new idea, but it’s still a meaningful one—and part of a larger effort to make every step of our process as responsible as possible

Beyond our own footprint.

Our sustainability efforts don’t stop with the product. From sourcing to supply chain, we’re working to raise the bar across the board. If our methods can help lead to a greener eyewear industry, we’re all in. The goal is progress—not just for us, but for everyone willing to build a better way.

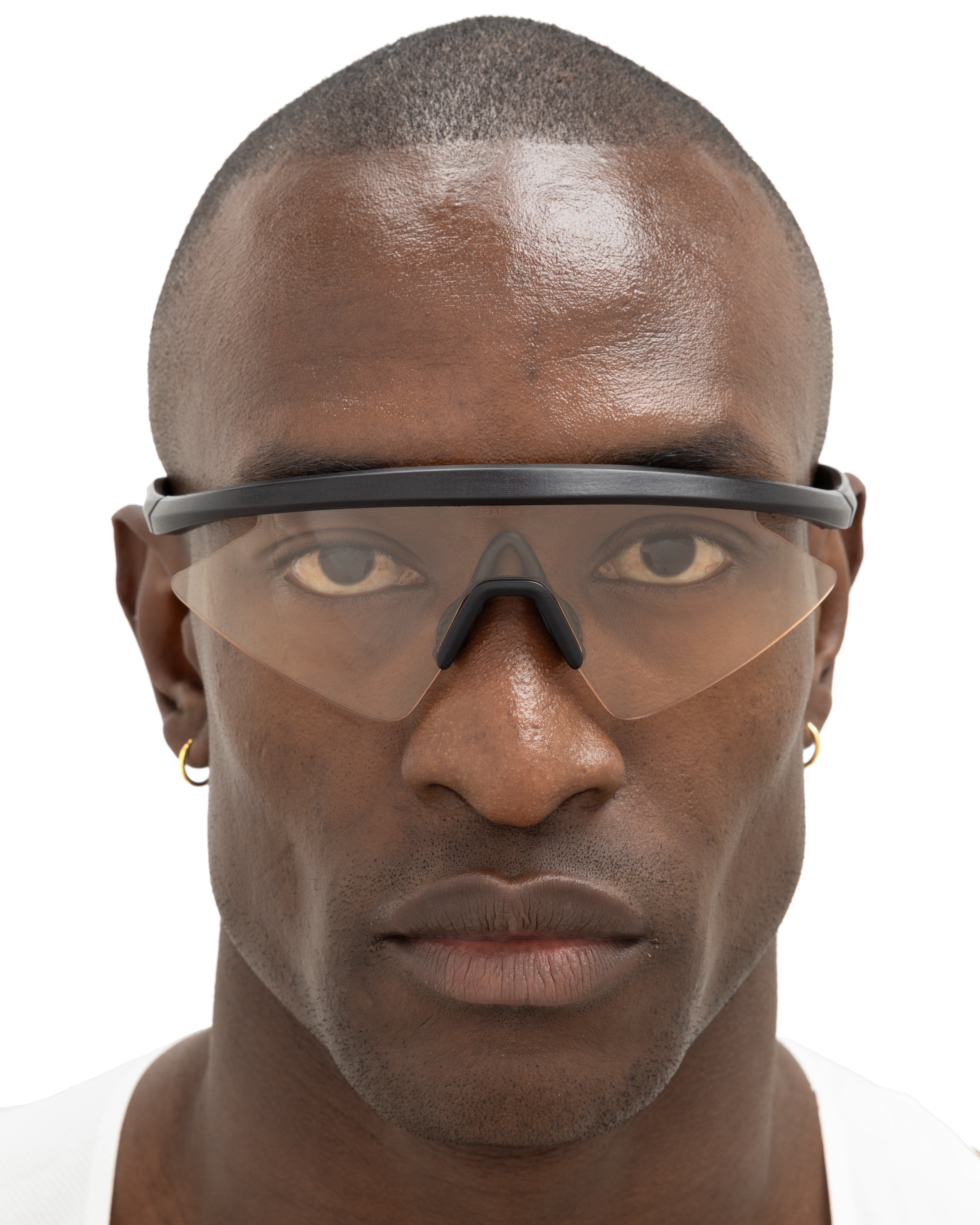

The collection

APEX: Black Night - Alpine Silver Rose.

APEX: Black Night - Bottomless Pit

APEX: Black Night - Evaporate Smoke

APEX: Forest Moss - Autumn Copper